- Product Detail

-

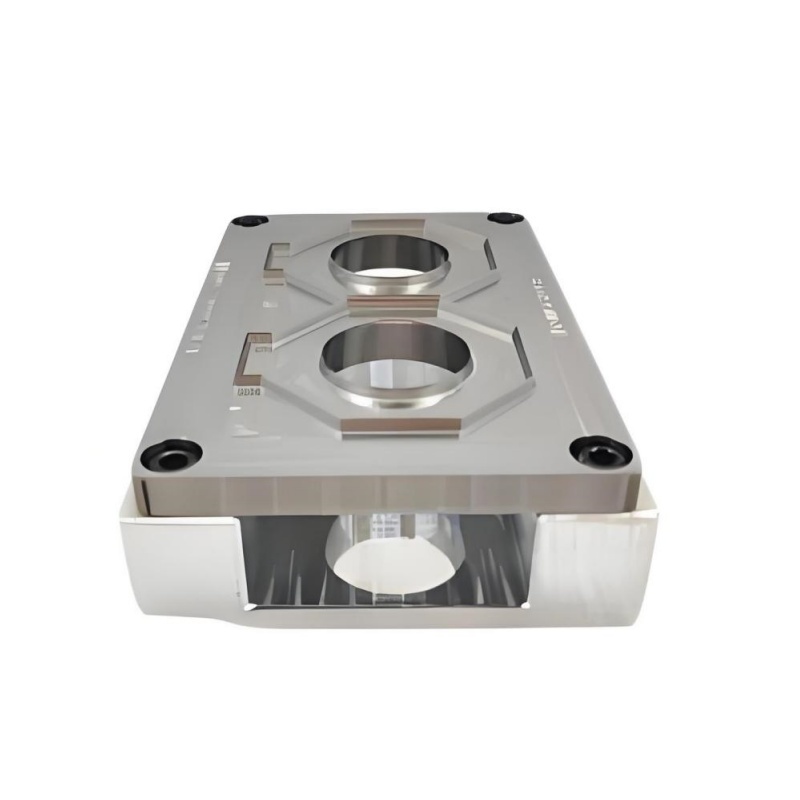

Carving Knife Die Mold

High hardness of the material used in the mold (HRC54-60), long life of the mold (cutting the same material is 3 times the etching die), the product can achieve automatic waste removal, can use a variety of ways to return the material, can make different blade angles according to product quality requirements, in order to achieve perfect die cutting, can do a variety of knife heights (0.5-6MM).The mold can be repaired back to the original factory (general mold can be repaired 3 times), and the mold accuracy after repair is high (+0.015MM).

Mainly used in: double-sided adhesive, self-adhesive, single-sided adhesive, foam, dust filter, hole die-cutting and other products.

Carving Knife Die Mold

High hardness of the material used in the mold (HRC54-60), long life of the mold (cutting the same material is 3 times the etching die), the product can achieve automatic waste removal, can use a variety of ways to return the material, can make different blade angles according to product quality requirements, in order to achieve perfect die cutting, can do a variety of knife heights (0.5-6MM), The mold can be repaired back to the original factory (general mold can be repaired 3 times), and the mold accuracy after repair is high (+0.015MM).

Subcategory:

Key Words:

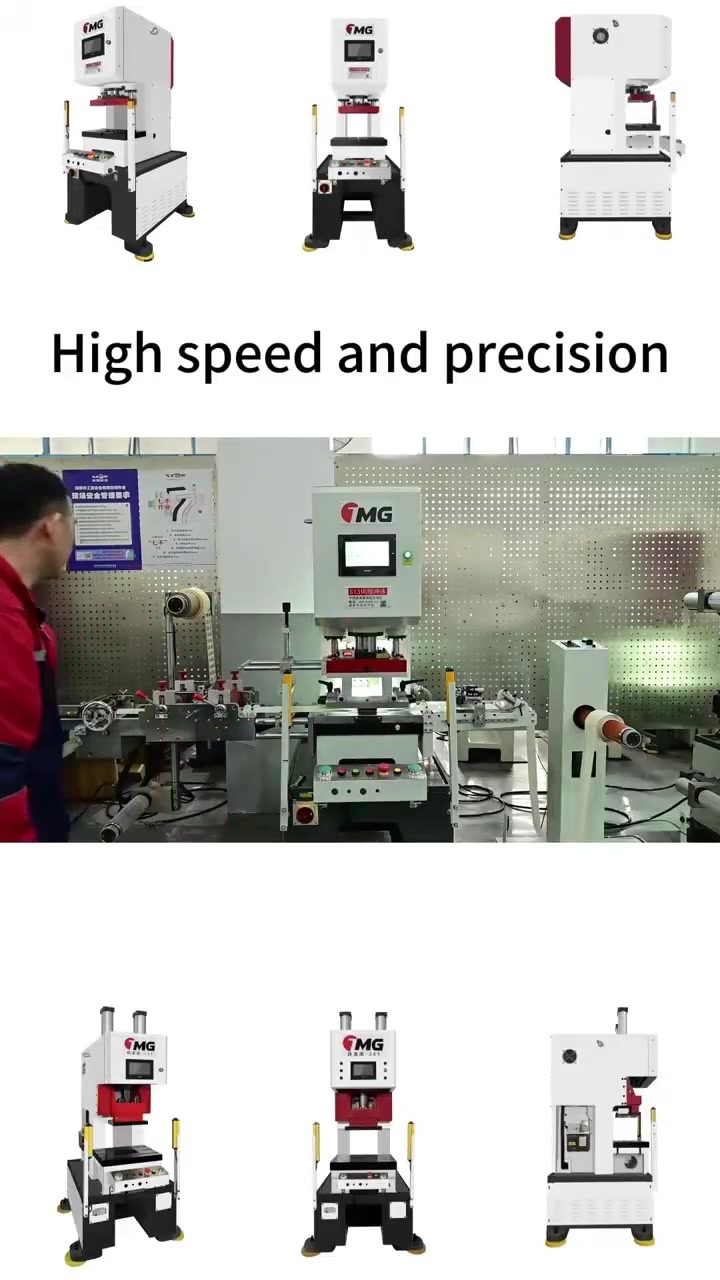

Factory

Shenzhen Xiaolisi Intelligent Technology Co., Ltd. Automation Equipment Factory specializes in the design and production of servo die-cutting machines, servo punches, stamping automation all-in-one machines and product mold customization. With more than 20 product development patents and 20 years of experience in the stamping field, the company has always pursued innovation and is a pioneer in applying die cutting to punch machines.

Product Function And Testing

It has the characteristics of high pressure, high speed, high precision, quiet, intelligent, safe, less vibration, and can be put upstairs

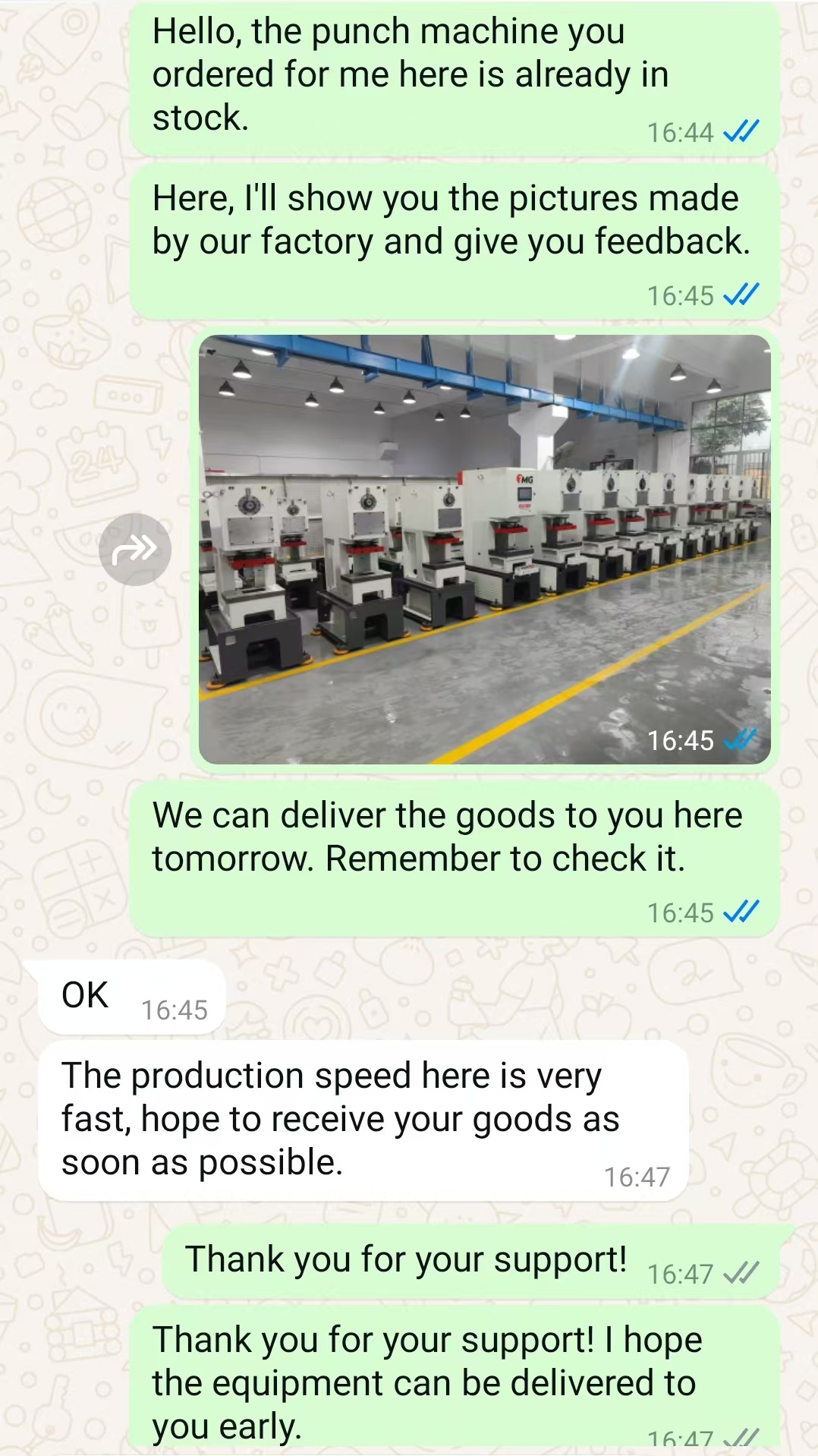

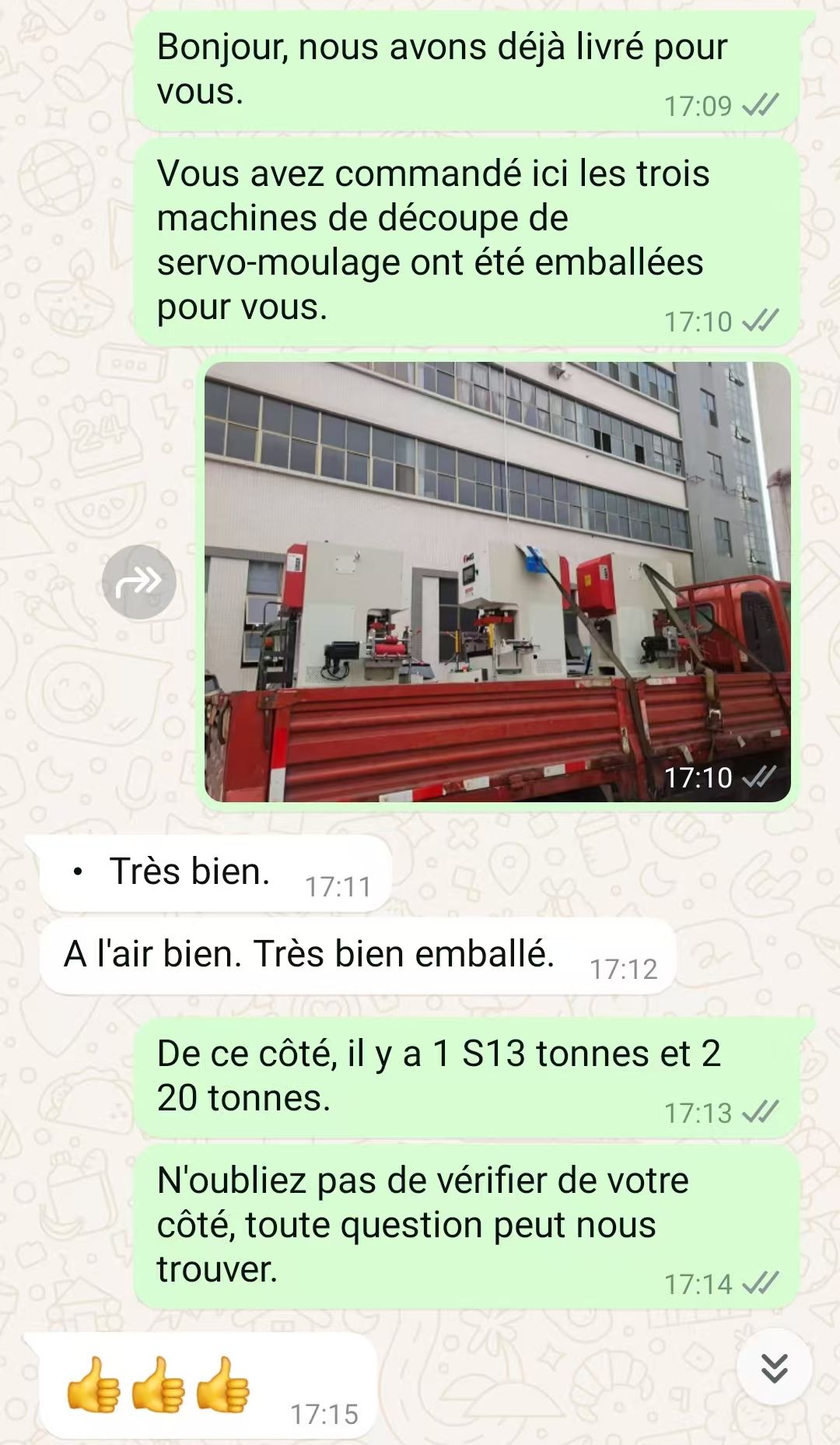

Customer Feedback

We are a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises, with advanced technical equipment and management experience, product performance is stable, high degree of automation.

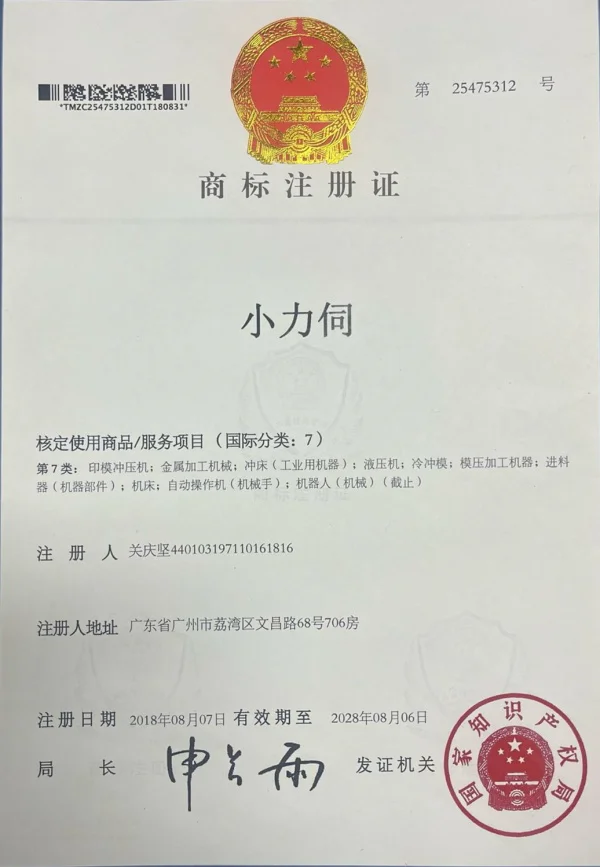

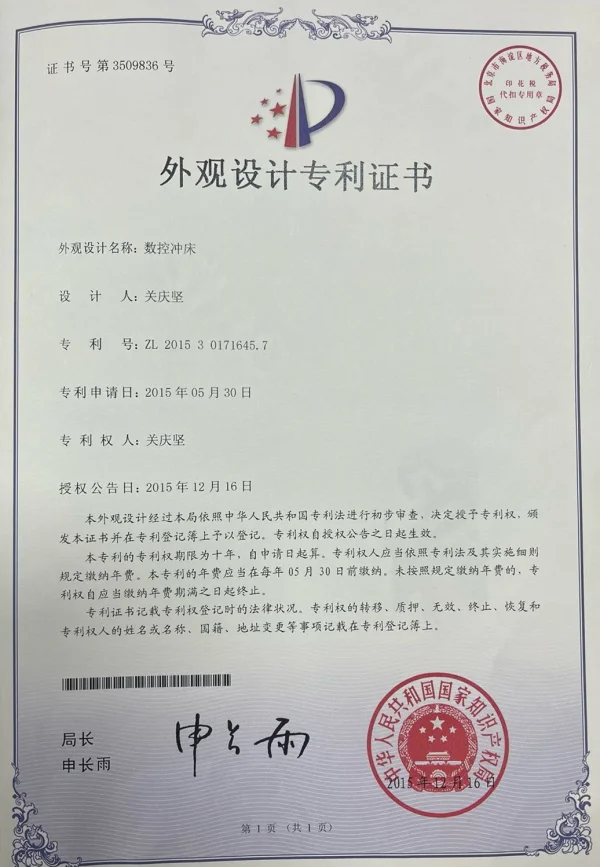

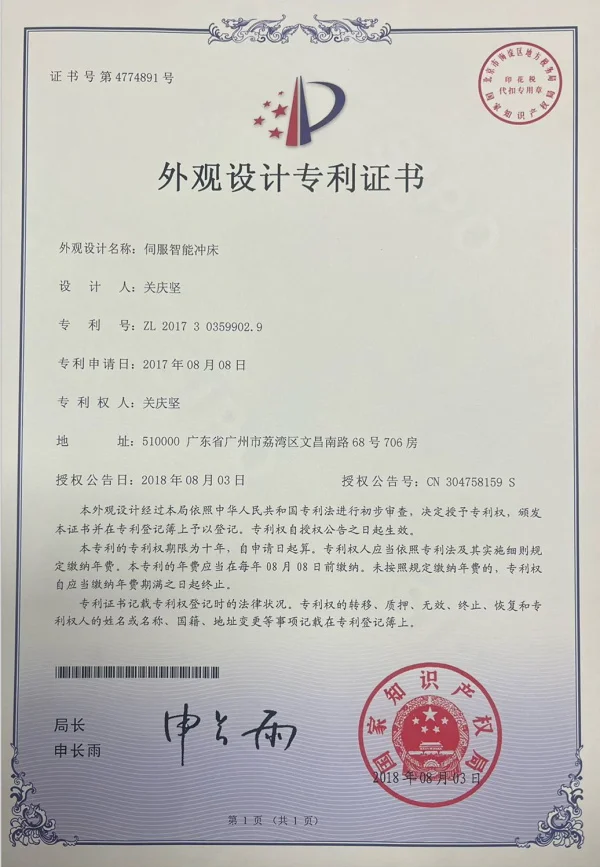

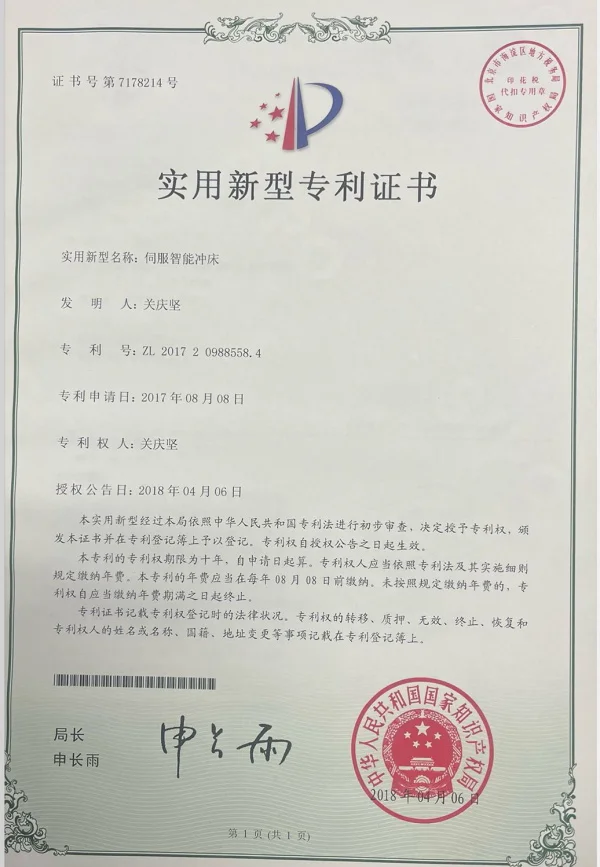

Certificate Honor

Business Partner

Shipping Packaging

Terms

1. Delivery time: 45 days after order

2.Payment terms: 30%TT in advance, balance before shipment

3. Warranty period: 1year

4. Technical service: available (online + offline)

5.Operation & maintenance manual (English Version) available

Warranty Policy

During the warranty period, free maintenance and replacement partsavailable if any quality problem underregular operation.(except for improper operation or man-made damage)

Installation Support

Our engineering team provides field maintenance and 24hr onlinesupport.

FAQ

Are you manufacturer or trader?

We are a manufacturer of die cutting presses with more than 20 years of experience in the die cutting industry.

What is your terms of payment?

T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

How about your delivery time?

Generally, it will take 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

What is your warranty policy?

We can supply one year warranty for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

Can you provide some videos of your factory and the machine working?

Yes, please visit our website to get more videos.

Related Products