Exploring the Latest Advancements in Metal Sheet Punching Machines

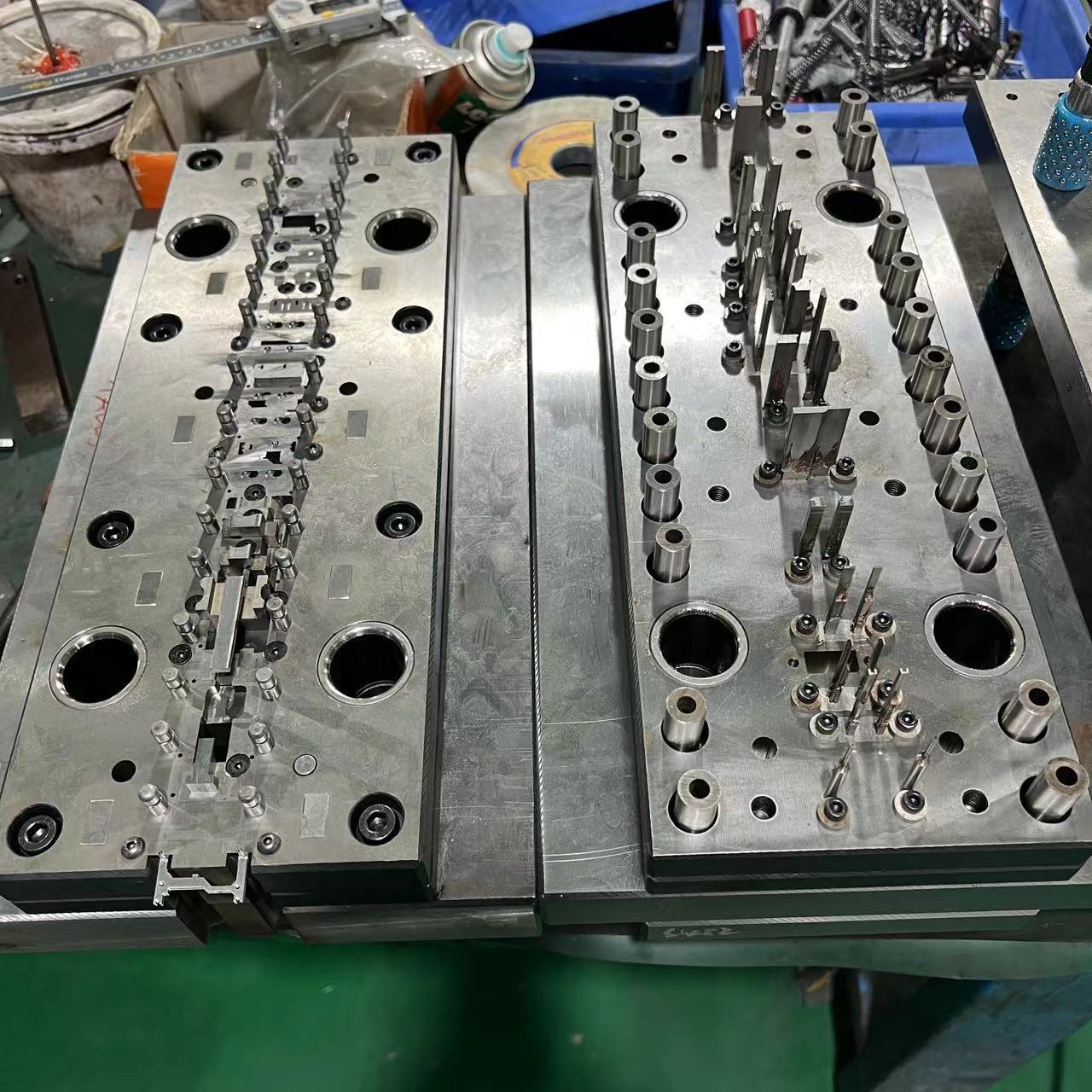

In the world of manufacturing and processing machinery, the newest metal sheet punching machines stand out as vital tools for industries like leather processing. These machines have evolved significantly, incorporating advanced technologies and innovative designs to meet the increasing demands for precision and efficiency in production.

The fundamental role of a metal sheet punching machine is to create holes or shapes in metal sheets through a process known as punching. This process is essential in various applications, particularly in the leather industry, where metal components are often needed for buckles, snaps, and other accessories. The newest models are equipped with features that enhance their capabilities, making them suitable for a wide range of materials beyond metal, including various grades of leather.

One of the key advancements in the newest metal sheet punching machines is the integration of CNC (Computer Numerical Control) technology. This feature allows for automated precision in the punching process, reducing the likelihood of human error and ensuring that each punch is executed with high accuracy. Operators can program complex patterns and designs, streamlining the production process and significantly reducing setup times.

Additionally, modern metal sheet punching machines come with enhanced safety features. With improved guarding systems and emergency stop functions, these machines prioritize operator safety while ensuring seamless workflow. The ergonomic designs also focus on operator comfort, minimizing fatigue and promoting a safer working environment.

Energy efficiency is another area where the newest machines excel. Many manufacturers are now producing equipment that consumes less energy, leading to reduced operational costs and a smaller environmental footprint. This is particularly important for businesses aiming to adopt more sustainable practices while maintaining high levels of productivity.

Furthermore, the versatility of these machines enables them to handle various sheet thicknesses and types of materials. This adaptability is crucial for manufacturers who require flexibility in their production lines, allowing them to shift between different projects without the need for extensive reconfiguration.

Maintenance and ease of use have also improved in these latest models. User-friendly interfaces and diagnostic tools allow operators to monitor the machine’s performance and address potential issues before they escalate. This proactive approach to maintenance ensures that machines remain operational, minimizing downtime and maximizing output.

In conclusion, the newest metal sheet punching machines are transforming the landscape of the leather processing and manufacturing industries. By embracing advanced technologies and focusing on efficiency, safety, and sustainability, these machines enable businesses to enhance their production capabilities and respond more effectively to market demands. For any company looking to improve its manufacturing processes, investing in such innovative machinery can lead to significant long-term benefits.

The fundamental role of a metal sheet punching machine is to create holes or shapes in metal sheets through a process known as punching. This process is essential in various applications, particularly in the leather industry, where metal components are often needed for buckles, snaps, and other accessories. The newest models are equipped with features that enhance their capabilities, making them suitable for a wide range of materials beyond metal, including various grades of leather.

One of the key advancements in the newest metal sheet punching machines is the integration of CNC (Computer Numerical Control) technology. This feature allows for automated precision in the punching process, reducing the likelihood of human error and ensuring that each punch is executed with high accuracy. Operators can program complex patterns and designs, streamlining the production process and significantly reducing setup times.

Additionally, modern metal sheet punching machines come with enhanced safety features. With improved guarding systems and emergency stop functions, these machines prioritize operator safety while ensuring seamless workflow. The ergonomic designs also focus on operator comfort, minimizing fatigue and promoting a safer working environment.

Energy efficiency is another area where the newest machines excel. Many manufacturers are now producing equipment that consumes less energy, leading to reduced operational costs and a smaller environmental footprint. This is particularly important for businesses aiming to adopt more sustainable practices while maintaining high levels of productivity.

Furthermore, the versatility of these machines enables them to handle various sheet thicknesses and types of materials. This adaptability is crucial for manufacturers who require flexibility in their production lines, allowing them to shift between different projects without the need for extensive reconfiguration.

Maintenance and ease of use have also improved in these latest models. User-friendly interfaces and diagnostic tools allow operators to monitor the machine’s performance and address potential issues before they escalate. This proactive approach to maintenance ensures that machines remain operational, minimizing downtime and maximizing output.

In conclusion, the newest metal sheet punching machines are transforming the landscape of the leather processing and manufacturing industries. By embracing advanced technologies and focusing on efficiency, safety, and sustainability, these machines enable businesses to enhance their production capabilities and respond more effectively to market demands. For any company looking to improve its manufacturing processes, investing in such innovative machinery can lead to significant long-term benefits.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News