Unlock Efficiency: The Benefits of a Customized Mini Punching Machine Feeder

Unlock Efficiency: The Benefits of a Customized Mini Punching Machine Feeder

In today’s competitive manufacturing landscape, efficiency is paramount. Companies continually seek innovative solutions to enhance productivity while minimizing costs. One such solution is the customized mini punching machine feeder. This specialized equipment not only optimizes the punching process but also leads to significant improvements in operational efficiency. In this article, we delve into the numerous benefits of adopting a customized mini punching machine feeder, detailing how it can transform your manufacturing capabilities.

Table of Contents

- Understanding Mini Punching Machines

- What is a Customized Mini Punching Machine Feeder?

- The Importance of Customization in Manufacturing

- Key Benefits of Customized Mini Punching Machine Feeders

- Efficiency in Operations

- Cost-Effectiveness and Return on Investment

- Versatility and Adaptability

- Ensuring Quality and Precision

- Future Trends in Mini Punching Machine Technology

- Frequently Asked Questions

- Conclusion

Understanding Mini Punching Machines

Mini punching machines are compact, efficient devices designed to create holes in various materials, including metal, plastic, and paper. They are fundamental in the manufacturing sector, particularly in industries such as electronics, automotive, and packaging. The compact size of these machines allows for easy integration into production lines, providing essential functionality without requiring extensive floor space.

Different Types of Mini Punching Machines

Mini punching machines come in various types, each tailored for specific applications. These include:

- Mechanical Punching Machines: Utilize a mechanical lever system to operate, providing a reliable punching solution.

- Hydraulic Punching Machines: Use hydraulic power to apply force, allowing for greater punching capabilities.

- Pneumatic Punching Machines: Operate using compressed air, offering quick and efficient punching solutions.

What is a Customized Mini Punching Machine Feeder?

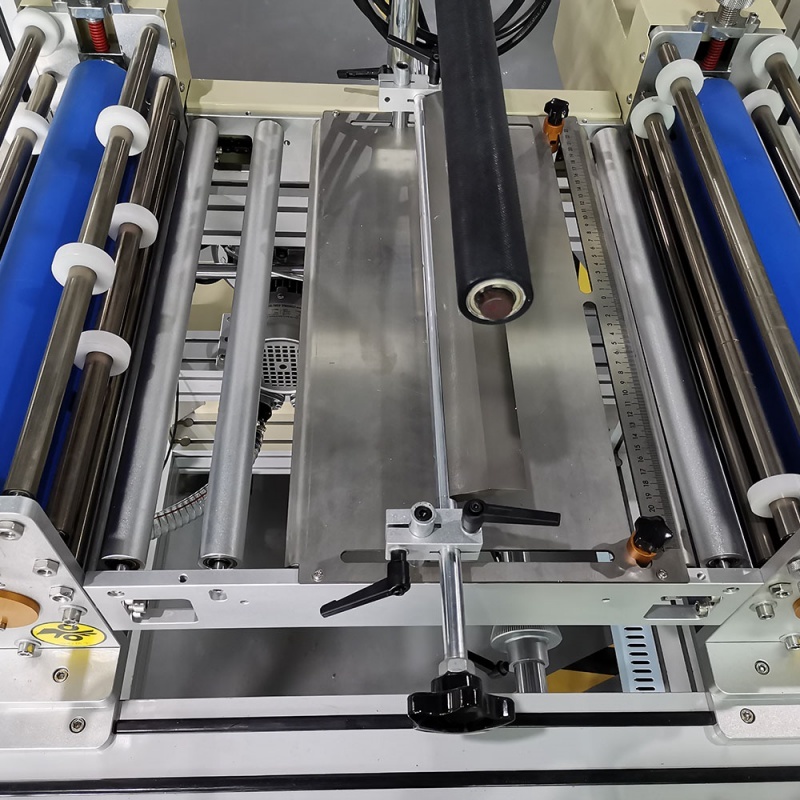

A customized mini punching machine feeder is an advanced attachment designed to automate and enhance the feeding process of materials into the punching machine. This customization allows manufacturers to tailor the feeder's specifications to meet their unique production requirements, significantly improving the overall efficiency of the punching operation.

Components of a Customized Mini Punching Machine Feeder

These feeders typically consist of various components, including:

- Feeding Mechanism: Ensures continuous and precise delivery of materials to the punching machine.

- Control System: Allows for the adjustment of feeding speed and material alignment.

- Sensor Technology: Detects material presence and ensures proper feeding, reducing waste.

The Importance of Customization in Manufacturing

Customization plays a crucial role in modern manufacturing. As industries evolve, the need for tailored solutions becomes increasingly apparent. A customized mini punching machine feeder provides several advantages over standard models, including:

- Enhanced Performance: Tailored solutions can address specific production challenges, resulting in better performance.

- Improved Compatibility: Custom feeders can be designed to work seamlessly with existing machinery, facilitating smoother operations.

- Unique Material Handling: Customization allows for the handling of diverse materials and product sizes.

Key Benefits of Customized Mini Punching Machine Feeders

Adopting a customized mini punching machine feeder can lead to numerous advantages for manufacturers:

- Increased Production Speed: Automation of the feeding process enables faster operation, enhancing overall throughput.

- Minimized Downtime: Custom feeders reduce the need for manual adjustments and material loading, minimizing production interruptions.

- Improved Worker Safety: Automation minimizes manual handling, reducing the risk of accidents in the workplace.

Enhancing Production Workflow

Custom mini punching machine feeders streamline the production workflow by ensuring that materials are delivered consistently and efficiently. This seamless integration enhances the overall productivity of the manufacturing process.

Efficiency in Operations

Efficiency is at the heart of successful manufacturing operations. Customized mini punching machine feeders contribute to operational efficiency by:

- Reducing Material Waste: Precise feeding minimizes the risk of waste due to misaligned materials.

- Optimizing Machine Usage: Enhanced feeding mechanisms ensure that machines operate at optimal capacity.

- Streamlining Maintenance: Custom designs can incorporate features that simplify maintenance and reduce downtime.

Cost-Effectiveness and Return on Investment

Investing in a customized mini punching machine feeder may seem substantial initially, but the long-term benefits often outweigh the costs:

- Lower Labor Costs: Automation decreases the reliance on manual labor, reducing overtime expenses.

- Higher Output: Increased production rates lead to higher output, enhancing overall profitability.

- Extended Equipment Lifespan: Efficient feeding reduces wear and tear on machinery, prolonging equipment life.

Calculating ROI on Customized Solutions

Manufacturers can calculate the return on investment (ROI) by analyzing improvements in productivity, reductions in labor costs, and savings from decreased material waste, allowing for informed decision-making regarding equipment investments.

Versatility and Adaptability

One of the standout features of customized mini punching machine feeders is their versatility. These feeders can be adapted to different materials, shapes, and sizes, making them suitable for various applications:

- Handling Diverse Materials: From soft plastics to hard metals, customized feeders can manage a wide range of materials.

- Accommodating Various Shapes: Tailored designs ensure compatibility with different product shapes, enhancing flexibility in production.

Ensuring Quality and Precision

Quality and precision are non-negotiable in manufacturing. Customized mini punching machine feeders enhance these aspects by:

- Improved Alignment: Custom feeders ensure that materials are aligned correctly before punching, reducing defects.

- Consistent Feeding: Automation ensures consistent feeding rates, contributing to uniform product quality.

Quality Control Measures

Integrating quality control measures within the feeding process can further enhance product quality, ensuring that only the best materials are processed.

Future Trends in Mini Punching Machine Technology

As technology advances, the future of mini punching machines and their feeders looks promising:

- Smart Technology Integration: The incorporation of IoT (Internet of Things) will allow for real-time monitoring and adjustments.

- AI-Driven Solutions: AI can optimize feeding processes based on historical data, enhancing efficiency.

Frequently Asked Questions

1. What materials can a customized mini punching machine feeder handle?

Customized mini punching machine feeders can handle a wide range of materials, including metals, plastics, and composites, tailored to your specific needs.

2. How does a customized feeder improve production speed?

By automating the feeding process, customized feeders eliminate manual handling and ensure continuous material flow, significantly increasing production speed.

3. What are the maintenance requirements for these feeders?

Maintenance requirements vary by design but typically include regular cleaning, lubrication of moving parts, and periodic inspections to ensure proper functionality.

4. How can I calculate ROI for a customized mini punching machine feeder?

To calculate ROI, consider factors like reduced labor costs, increased output, and savings from minimized material waste. Comparing these benefits against the initial investment will provide a clear picture.

5. Can these feeders be integrated with existing machinery?

Yes, customized mini punching machine feeders are designed to work seamlessly with existing machinery, providing a smooth integration into your production line.

Conclusion

Investing in a customized mini punching machine feeder presents a range of benefits for manufacturers looking to enhance productivity, reduce costs, and ensure quality. By optimizing the feeding process, these machines contribute significantly to operational efficiency while accommodating various materials and product requirements. As manufacturing technology continues to evolve, the importance of tailored solutions will only grow, making customized feeders an essential component of modern production lines. Embracing this innovation not only facilitates immediate gains in efficiency but also sets the foundation for future advancements. Unlock the potential of your manufacturing operations by exploring the advantages of customized mini punching machine feeders today.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News