How Pneumatic Servo Press Feeders Revolutionize Material Handling in Industrial Settings

How Pneumatic Servo Press Feeders Revolutionize Material Handling in Industrial Settings

Table of Contents

- Introduction

- Understanding Pneumatic Servo Press Feeders

- Benefits of Pneumatic Servo Press Feeders in Material Handling

- Applications Across Various Industries

- Choosing the Right Pneumatic Servo Press Feeder

- Common Issues and Solutions

- Future Trends in Pneumatic Servo Press Feeders

- Conclusion

- FAQs

Introduction

In the fast-paced world of manufacturing and production, the ability to handle materials efficiently is crucial. **Pneumatic servo press feeders** have emerged as a vital tool in this context, providing solutions that enhance material handling processes. By leveraging advanced pneumatic technology, these feeders not only streamline operations but also improve overall productivity. This article explores the mechanics, benefits, and applications of pneumatic servo press feeders, shedding light on how they can revolutionize your material handling practices.

Understanding Pneumatic Servo Press Feeders

To appreciate the advantages of pneumatic servo press feeders, it is essential to understand their design and functionality.

The Mechanics Behind Pneumatic Servo Press Feeders

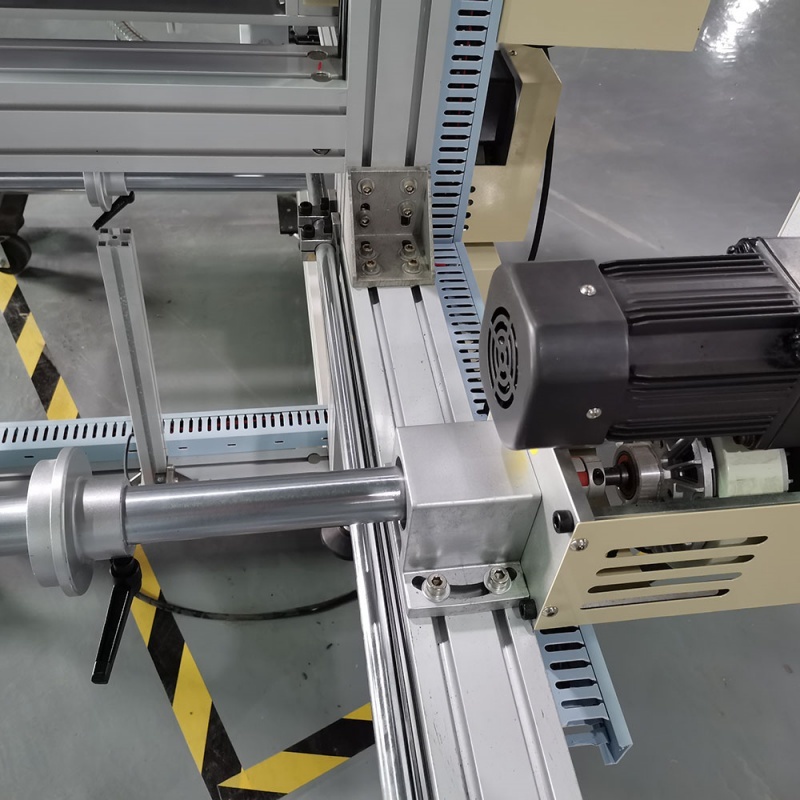

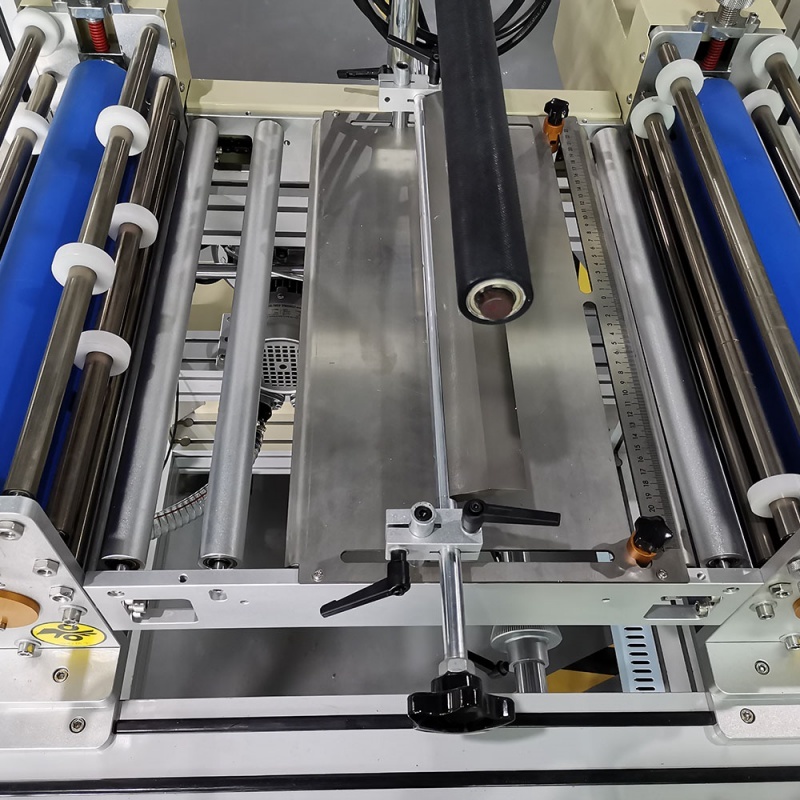

Pneumatic servo press feeders combine **pneumatics** and **servo technology**, working in tandem to deliver precise control over material handling. The heart of these feeders is the pneumatic actuator, which uses compressed air to produce linear motion. This motion is then finely controlled by a servo motor, allowing for rapid adjustments in speed and force.

The **interaction between pneumatic systems and servo motors** ensures that material is fed into the press with minimal delay and maximal accuracy. This synergy results in enhanced performance metrics, making it a valuable asset in manufacturing.

Key Components of Pneumatic Servo Press Feeders

The effectiveness of pneumatic servo press feeders can be attributed to several essential components:

- **Pneumatic Actuator**: Converts compressed air into mechanical motion.

- **Servo Motor**: Provides precise control of the feeder's movements.

- **Control System**: Allows operators to adjust settings and monitor performance.

- **Feeding Mechanism**: Ensures consistent delivery of materials to the press.

Each of these components plays a critical role in the overall functionality, contributing to a cohesive and efficient material handling process.

Benefits of Pneumatic Servo Press Feeders in Material Handling

Implementing pneumatic servo press feeders in your production line can yield significant benefits, ranging from improved efficiency to enhanced safety.

Increased Efficiency

One of the primary advantages of pneumatic servo press feeders is their ability to increase operational efficiency. By automating the feeding process, these feeders significantly reduce the time required to prepare materials for pressing. **Faster cycle times** mean higher throughput, allowing manufacturers to meet demand without compromising quality.

Moreover, the ability to program these feeders for various materials and tasks enhances flexibility, making it easier to adapt to changing production requirements.

Improved Precision

Precision is paramount in manufacturing, and pneumatic servo press feeders excel in this area. With their advanced control systems, these feeders can deliver materials with exceptional accuracy, minimizing the risk of errors that can result in costly rework or scrap.

**Consistent feeding** ensures uniformity in the final product, which is particularly important in industries such as automotive or electronics, where tolerances are tight and quality assurance is critical.

Enhanced Safety Features

Safety is a non-negotiable aspect of any industrial operation. Pneumatic servo press feeders incorporate several safety features designed to protect both operators and machinery. These can include:

- **Emergency Stop Mechanisms**: Quick response systems that halt operations instantly.

- **Safety Shields**: Physical barriers that prevent accidental contact with moving parts.

- **Sensor Technology**: Detects anomalies in operation, triggering alerts or shutdowns.

By prioritizing safety, manufacturers can create a work environment that minimizes risks and promotes employee well-being.

Applications Across Various Industries

Pneumatic servo press feeders find applications across a wide range of industries, showcasing their versatility and effectiveness.

- **Automotive Manufacturing**: Used for stamping and shaping metal components, ensuring precise material placement.

- **Electronics**: Essential for handling delicate parts, where precision and care are paramount.

- **Packaging**: Automates the insertion of materials into packaging lines, enhancing speed and efficiency.

- **Aerospace**: Vital for manufacturing complex components that require exact specifications.

Each of these applications benefits from the unique capabilities of pneumatic servo press feeders, helping to address industry-specific challenges effectively.

Choosing the Right Pneumatic Servo Press Feeder

Selecting the appropriate pneumatic servo press feeder involves several considerations to ensure optimal performance in your specific application.

- **Material Type**: Different materials may require different feeding mechanisms; understanding your material is crucial.

- **Production Volume**: Assessing the volume of materials to be processed will help determine the feeder's capacity needs.

- **Control Requirements**: Consider how much control you need over the feeding process and whether programmable settings are necessary.

- **Budget Constraints**: Balancing performance with cost will help you find a feeder that meets your needs without exceeding your budget.

By carefully evaluating these factors, you can ensure that you invest in a pneumatic servo press feeder that aligns with your operational goals.

Common Issues and Solutions

While pneumatic servo press feeders are highly efficient, they are not without their challenges. Understanding potential issues can help you maintain smooth operations.

- **Air Leaks**: One common issue is air leaks within the pneumatic system. Regular maintenance and inspections can help identify and rectify these leaks promptly.

- **Servo Motor Malfunction**: If the servo motor fails, it can disrupt the entire feeding process. Keeping spare motors on hand and performing routine checks can mitigate this risk.

- **Control System Errors**: Software glitches may occur in the control system. Ensuring that your software is updated regularly can help prevent these issues.

By being proactive about maintenance and troubleshooting, you can minimize downtime and maintain productivity.

Future Trends in Pneumatic Servo Press Feeders

As technology continues to evolve, pneumatic servo press feeders are expected to undergo significant advancements. Key trends to watch include:

- **Integration with IoT**: The adoption of Internet of Things (IoT) technology will enable smarter feeding systems that can communicate with other machinery for optimized operations.

- **Enhanced Automation**: Increased automation will streamline operations further, reducing the need for manual intervention and enhancing efficiency.

- **Customization Options**: As manufacturers seek tailored solutions, the market for customizable pneumatic servo press feeders will likely expand, allowing for specific adaptations to meet unique production needs.

Staying informed about these trends can help manufacturers remain competitive and leverage the latest innovations in material handling technology.

Conclusion

Pneumatic servo press feeders represent a significant advancement in material handling technology within industrial settings. By improving efficiency, precision, and safety, these feeders can transform production processes and enable manufacturers to meet modern demands effectively. As industries continue to evolve, the adoption of pneumatic servo press feeders will likely play a crucial role in enhancing operational capabilities and driving growth. Investing in these systems today means preparing for a more efficient and productive tomorrow.

FAQs

1. What is a pneumatic servo press feeder?

A pneumatic servo press feeder is a device that uses compressed air and servo technology to automate the feeding of materials into industrial presses, enhancing efficiency and precision.

2. What industries benefit from using pneumatic servo press feeders?

Industries such as automotive, electronics, packaging, and aerospace benefit significantly from the implementation of pneumatic servo press feeders.

3. How do I maintain a pneumatic servo press feeder?

Regular maintenance includes checking for air leaks, inspecting the servo motor, and updating the control software to ensure optimal performance.

4. Can pneumatic servo press feeders handle various materials?

Yes, pneumatic servo press feeders are versatile and can be adapted to handle various materials, including metals, plastics, and delicate components.

5. What are the safety features of pneumatic servo press feeders?

Common safety features include emergency stop mechanisms, safety shields, and sensor technology to monitor operations and prevent accidents.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News