Unlocking Precision: Customized Mini Servo Hydraulic Press Solutions for Your Industrial Needs

Unlocking Precision: Customized Mini Servo Hydraulic Press Solutions

Table of Contents

- 1. Introduction to Mini Servo Hydraulic Press Solutions

- 2. What is a Mini Servo Hydraulic Press?

- 3. Advantages of Customized Mini Servo Hydraulic Press Solutions

- 4. Applications in Various Industries

- 5. How to Choose the Right Mini Servo Hydraulic Press

- 6. The Technology Behind Mini Servo Hydraulics

- 7. Maintenance and Support for Optimal Performance

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Mini Servo Hydraulic Press Solutions

In the ever-evolving landscape of industrial manufacturing, the demand for precision and efficiency has never been higher. **Mini servo hydraulic presses** are at the forefront of this revolution, offering tailored solutions that meet the specific needs of various industries. Unlike traditional hydraulic presses, these advanced machines utilize servo technology to deliver unmatched accuracy and control, making them ideal for tasks ranging from metal forming to assembly operations.

This article delves into the world of customized mini servo hydraulic press solutions, exploring their features, advantages, and diverse applications. We aim to provide a comprehensive understanding of how these machines can enhance operational efficiency and precision in your manufacturing processes.

2. What is a Mini Servo Hydraulic Press?

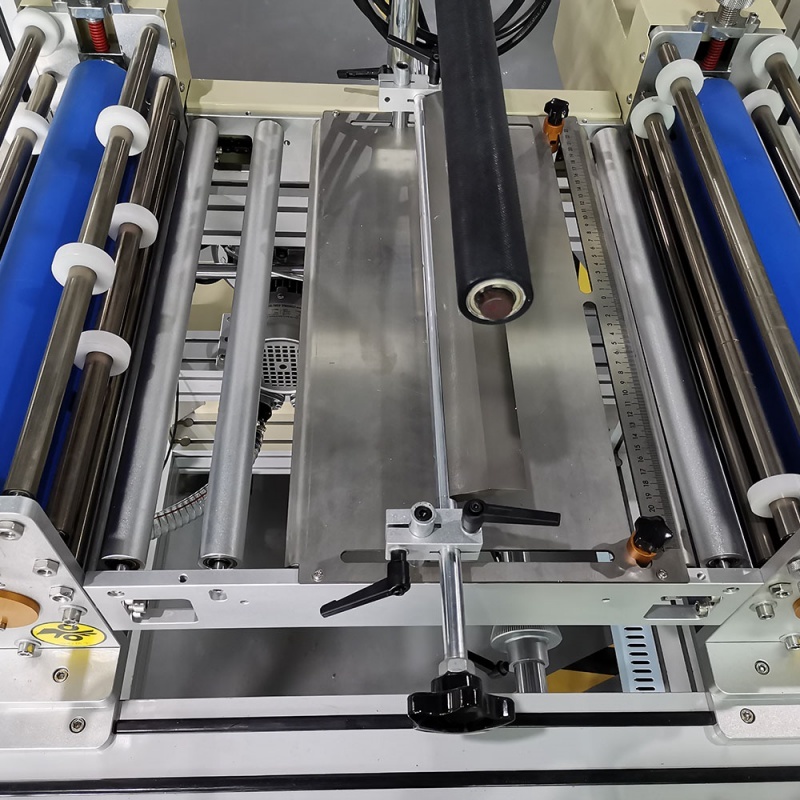

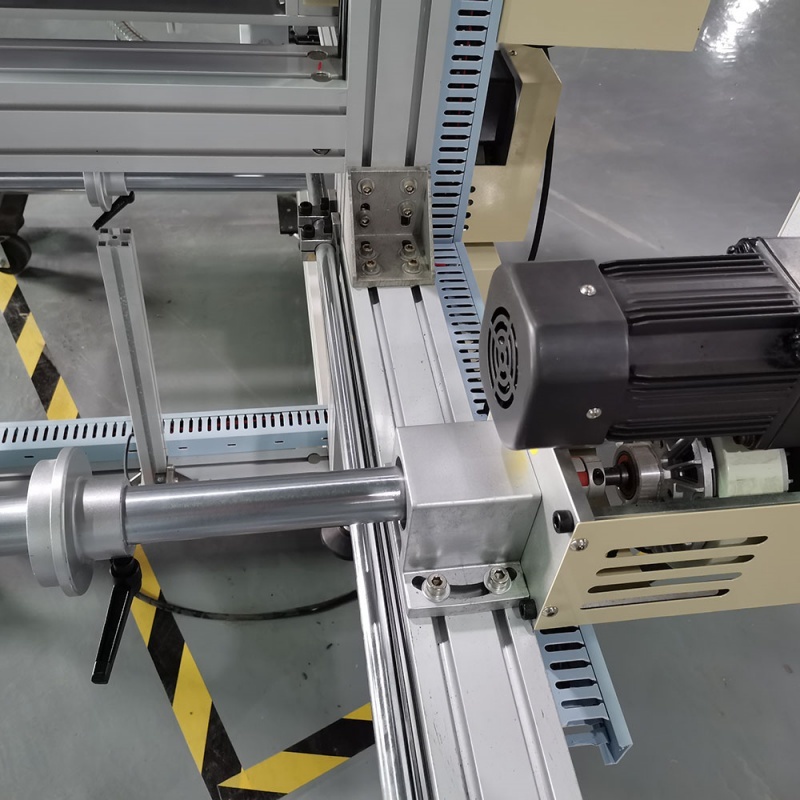

A mini servo hydraulic press is a compact hydraulic machine designed to exert force on materials using servo-controlled actuators. **The integration of servo technology** allows for precise control over speed, position, and force, ensuring that each operation is executed with high fidelity. These presses can be customized to meet the specific requirements of different applications, making them a versatile choice for many industries.

**Key components** of a mini servo hydraulic press include:

- **Servo Motor**: Provides precise control over the press's movements.

- **Hydraulic Cylinder**: Generates force by converting hydraulic energy into mechanical energy.

- **Control Unit**: Manages the operation of the press, allowing for adjustments in real time.

- **Frame**: Offers stability and support for the hydraulic components.

Together, these components facilitate a range of tasks, ensuring that users can achieve their manufacturing goals with enhanced precision.

3. Advantages of Customized Mini Servo Hydraulic Press Solutions

The adoption of mini servo hydraulic presses presents numerous advantages for manufacturers seeking to improve their operations. Here are the primary benefits:

3.1 Enhanced Precision and Accuracy

Using servo motors allows for **highly accurate positioning**, minimizing the risk of errors during the manufacturing process. This precision is particularly important in applications that require tight tolerances.

3.2 Improved Energy Efficiency

Unlike traditional hydraulic presses that operate continuously, mini servo hydraulic presses use energy only when necessary. This **on-demand operation** leads to significant energy savings, reducing overall operational costs.

3.3 Reduced Cycle Times

With faster response times and the ability to execute complex movements, these presses can complete tasks more quickly, resulting in **shorter cycle times** and increased productivity.

3.4 Customization Options

Manufacturers can tailor mini servo hydraulic presses to meet their specific needs. Customization options include varying force capacities, stroke lengths, and control systems, making it possible to create a machine that perfectly fits the application.

3.5 Low Noise Operation

Servo hydraulic presses operate more quietly than their traditional counterparts, creating a more pleasant working environment and reducing noise pollution.

4. Applications in Various Industries

Mini servo hydraulic presses are versatile machines that find applications across several industries. Here are some notable uses:

4.1 Automotive Industry

In the automotive sector, these presses are used for **stamping, forming, and assembly processes**. Their precision helps manufacturers produce components that meet stringent quality standards.

4.2 Electronics Manufacturing

The electronics industry benefits from mini servo hydraulic presses for tasks such as **inserting components into circuit boards** and assembling delicate parts, where accuracy is crucial.

4.3 Aerospace Sector

In aerospace manufacturing, precision is paramount. Mini servo hydraulic presses are employed for **component fabrication and assembly**, ensuring that parts meet rigorous safety and performance standards.

4.4 Medical Device Production

The medical industry relies on these presses for **fabricating components** used in medical devices, where precision and reliability are essential.

4.5 General Manufacturing

From small businesses to large-scale manufacturers, mini servo hydraulic presses are utilized for various manufacturing tasks, including **shaping, cutting, and assembling materials**.

5. How to Choose the Right Mini Servo Hydraulic Press

Selecting the right mini servo hydraulic press involves several considerations. Here are key factors to help guide your decision:

5.1 Assess Your Application Requirements

Understand the specific needs of your application, including the materials involved, the required force output, and the desired cycle time.

5.2 Evaluate Customization Options

Look for presses that offer customization capabilities to ensure the machine meets your exact specifications. Consider factors such as stroke length, force capacity, and control systems.

5.3 Consider Space and Layout

Mini servo hydraulic presses come in various sizes. Evaluate your shop floor layout to ensure that the chosen press fits within the available space.

5.4 Analyze Cost vs. Benefits

While cost is an important factor, evaluate the long-term benefits such as energy savings, reduced cycle times, and improved precision to determine the overall value.

5.5 Check for After-Sales Support and Maintenance

Choose a supplier that offers comprehensive after-sales support, including maintenance services and access to spare parts, to ensure optimal performance over time.

6. The Technology Behind Mini Servo Hydraulics

Understanding the technology behind mini servo hydraulic presses is crucial for recognizing their advantages. These machines utilize a combination of hydraulic and servo technologies to achieve unprecedented levels of control and efficiency.

6.1 Servo Motor Control

At the heart of the mini servo hydraulic press is the servo motor, which provides feedback on position, speed, and torque. This feedback allows for precise adjustments during operation, significantly enhancing accuracy.

6.2 Hydraulic Systems

The hydraulic system employs hydraulic fluid to transmit force, allowing for significant power generation in a compact form. This system is designed to work efficiently with the servo motor, ensuring smooth operation.

6.3 Advanced Control Algorithms

Modern mini servo hydraulic presses are equipped with advanced control algorithms that optimize performance by managing the interaction between the servo motor and hydraulic system, leading to enhanced productivity.

7. Maintenance and Support for Optimal Performance

To ensure your mini servo hydraulic press operates at peak performance, regular maintenance is essential. Here are some tips for effective maintenance:

7.1 Regular Inspections

Conduct regular inspections to check for signs of wear and tear, ensuring that all components are functioning as intended.

7.2 Lubrication

Maintain proper lubrication of moving parts to reduce friction and prevent damage, extending the life of the press.

7.3 Software Updates

Keep the control software up to date to benefit from the latest enhancements and ensure optimal performance.

7.4 Professional Servicing

Consider engaging professional servicing for complex maintenance tasks to prevent disruption in operations.

8. Frequently Asked Questions

8.1 What industries benefit most from mini servo hydraulic presses?

Mini servo hydraulic presses are widely used in the automotive, electronics, aerospace, medical, and general manufacturing industries.

8.2 How do I determine the right force capacity for my press?

Assess the materials and tasks involved in your application to determine the necessary force capacity. Consulting with a manufacturer can also provide guidance.

8.3 Are mini servo hydraulic presses energy-efficient?

Yes, they are designed to use energy efficiently, operating only when necessary and significantly reducing overall energy costs.

8.4 Can these presses be customized for specific applications?

Absolutely. Mini servo hydraulic presses can be tailored to meet specific requirements regarding force, stroke length, and control systems.

8.5 What kind of maintenance do mini servo hydraulic presses require?

Regular inspections, lubrication, software updates, and professional servicing are essential for maintaining optimal performance.

9. Conclusion

In a world where precision and efficiency are paramount, **customized mini servo hydraulic press solutions** stand out as an essential tool for various industries. These machines offer numerous advantages, including enhanced accuracy, energy efficiency, and customization options. By understanding their technology and applications, manufacturers can leverage these presses to optimize their production processes.

Investing in a mini servo hydraulic press can lead to significant improvements in manufacturing quality and productivity. As industries continue to evolve, embracing advanced technologies like these presses will be critical for staying competitive in today’s market.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News