Revolutionizing Leather Processing: The Advanced Multifunction Cutting and Punching Machine

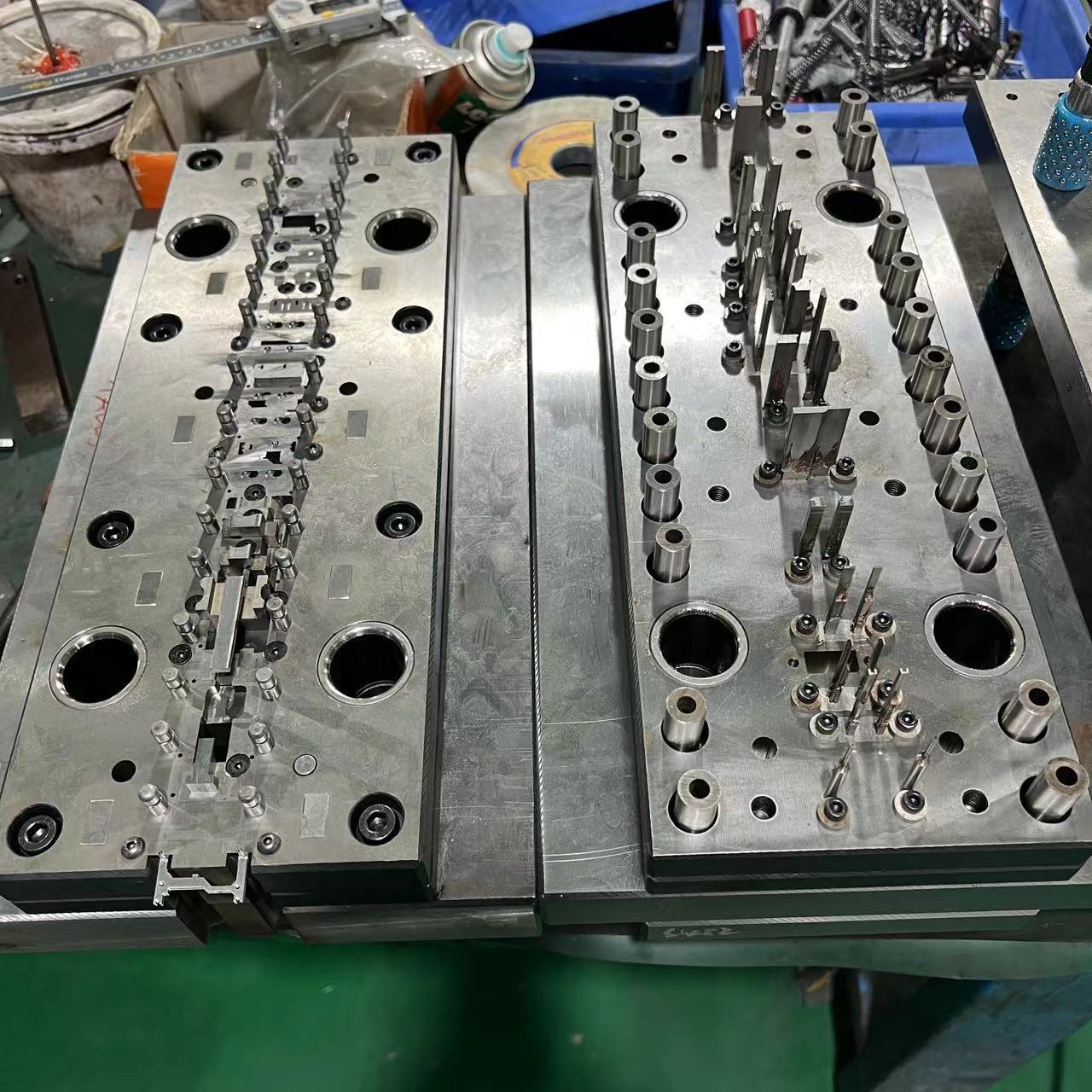

In the realm of leather processing, precision and efficiency are paramount. The advanced multifunction cutting and punching machine stands out as a revolutionary tool designed to meet the evolving demands of the manufacturing industry. These machines are engineered to perform multiple operations, such as cutting, punching, and sometimes even embossing, all within a single unit. This multifunctionality not only saves space but also significantly reduces production time, making it an invaluable asset for manufacturers.

One of the key benefits of the advanced multifunction cutting and punching machine is its ability to handle a variety of materials. While primarily designed for leather, these machines can often work with synthetic materials, textiles, and other substrates. This versatility allows manufacturers to diversify their product offerings without the need for multiple machines. By facilitating the processing of different materials, businesses can adapt to changing market trends and consumer demands more effectively.

Precision is another critical factor in leather manufacturing, and this machine excels in delivering high-quality results. With advanced technology and software integration, operators can achieve intricate designs with precise cuts and consistent punch placements. This accuracy reduces material waste and enhances the overall quality of the finished products, leading to higher customer satisfaction. As a result, the investment in such technology pays off in both the short and long term.

Moreover, the automation features of advanced multifunction cutting and punching machines contribute significantly to efficiency. With user-friendly interfaces, operators can quickly set up production runs and make adjustments as needed. This ease of use minimizes downtime and allows manufacturers to maximize their output. Additionally, many of these machines come equipped with safety features that protect operators while ensuring compliance with industry regulations—a crucial aspect in today's manufacturing environment.

Furthermore, the integration of smart technology in these machines allows for data collection and analysis, enabling manufacturers to monitor their production processes closely. This data-driven approach aids in identifying bottlenecks, optimizing workflows, and ultimately improving the overall efficiency of the manufacturing process.

In conclusion, the advanced multifunction cutting and punching machine represents a significant advancement in leather processing technology. By combining precision, versatility, and efficiency, this machine not only enhances production capabilities but also contributes to a more sustainable manufacturing process. As the leather industry continues to evolve, embracing such innovative machinery will be crucial for businesses aiming to stay competitive in a fast-paced market. By investing in advanced multifunction cutting and punching machines, manufacturers are not just improving their operations; they are positioning themselves for future success in a dynamic environment.

One of the key benefits of the advanced multifunction cutting and punching machine is its ability to handle a variety of materials. While primarily designed for leather, these machines can often work with synthetic materials, textiles, and other substrates. This versatility allows manufacturers to diversify their product offerings without the need for multiple machines. By facilitating the processing of different materials, businesses can adapt to changing market trends and consumer demands more effectively.

Precision is another critical factor in leather manufacturing, and this machine excels in delivering high-quality results. With advanced technology and software integration, operators can achieve intricate designs with precise cuts and consistent punch placements. This accuracy reduces material waste and enhances the overall quality of the finished products, leading to higher customer satisfaction. As a result, the investment in such technology pays off in both the short and long term.

Moreover, the automation features of advanced multifunction cutting and punching machines contribute significantly to efficiency. With user-friendly interfaces, operators can quickly set up production runs and make adjustments as needed. This ease of use minimizes downtime and allows manufacturers to maximize their output. Additionally, many of these machines come equipped with safety features that protect operators while ensuring compliance with industry regulations—a crucial aspect in today's manufacturing environment.

Furthermore, the integration of smart technology in these machines allows for data collection and analysis, enabling manufacturers to monitor their production processes closely. This data-driven approach aids in identifying bottlenecks, optimizing workflows, and ultimately improving the overall efficiency of the manufacturing process.

In conclusion, the advanced multifunction cutting and punching machine represents a significant advancement in leather processing technology. By combining precision, versatility, and efficiency, this machine not only enhances production capabilities but also contributes to a more sustainable manufacturing process. As the leather industry continues to evolve, embracing such innovative machinery will be crucial for businesses aiming to stay competitive in a fast-paced market. By investing in advanced multifunction cutting and punching machines, manufacturers are not just improving their operations; they are positioning themselves for future success in a dynamic environment.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News